加拿大政府為了減少亞伯達省油砂開採釋放出的溫室氣體,將投資興建一座藻類生質精煉示範廠,將二氧化碳轉化為商業產品。

此藻類碳轉換試驗計畫(Algal Carbon Conversion Pilot Project)為期三年,由加拿大國家研究院(NRC)、加拿大天然資源有限公司(Canadian Natural Resources Limited)和池塘生質燃料公司(Pond Biofuels)合作,預計在加拿大天然資源有限公司於亞伯達省波尼維勒(Bonnyville)附近的Primrose South油砂場建造價值1900萬加幣的獨特設施,利用藻類回收油砂設施排放出的工業二氧化碳,並將其轉換成商業產品(如生質燃料)。

此藻類碳轉換試驗計畫(Algal Carbon Conversion Pilot Project)為期三年,由加拿大國家研究院(NRC)、加拿大天然資源有限公司(Canadian Natural Resources Limited)和池塘生質燃料公司(Pond Biofuels)合作,預計在加拿大天然資源有限公司於亞伯達省波尼維勒(Bonnyville)附近的Primrose South油砂場建造價值1900萬加幣的獨特設施,利用藻類回收油砂設施排放出的工業二氧化碳,並將其轉換成商業產品(如生質燃料)。

新工廠將利用二氧化碳培養綠藻,藉由藻類行光合作用來回收二氧化碳,最終成為藻類生質( algal biomass)。進一步加工藻類生質,可以製造諸如生質燃料、牲畜飼料和肥料等產品。加拿大科技部長古德伊爾(Gary Goodyear)表示,「這項發現具有龐大潛力,對我們的環境和經濟有助益,並能讓加拿大進一步成為管理二氧化碳排放的領先者。」

除了減少二氧化碳排放,藻類碳轉換技術也提供廢水和餘熱處理的新可能。加拿大天然資源有限公司的總裁勞特(Steve Laut)表示,「加拿大天然資源有限公司是加拿大最大的獨立原油及天然氣生產商之一,很榮幸能與NRC及池塘生質燃料公司合作進行這項減少碳足跡的計畫。」他補充,「我們也會持續改進技術,讓工廠的運作能提供改進環境的效果。」加拿大天然資源有限公司也在8月初表示,該公司的Primrose East和Primrose South生產基地的四個地點,外洩將近100萬公升的瀝青到環境中。然而藻類生質精煉示範廠就預計設在Primrose South。

不過,之前加拿大天然資源有限公司的老舊油井出現「機械故障」,造成瀝青和水的混合物滲入亞伯達省的「冷湖機載武器靶區」(Cold Lake Air Weapons Range)。勞特告訴加拿大電視新聞網(CTV News),目前已經傷害控制在一個13.5公頃的區域,也回收了「相當程度」的污染油。雖然瀝青仍然滲出地面,但速度正不斷下降。

加拿大天然資源有限公司是利用水平管道將高壓蒸汽注入瀝青儲存點,亞伯達省的監管機構已暫停並限制Primrose基地的運作,正在調查洩漏的原因。不過亞伯達省能源監管機構早在2009年,就報導過加拿大天然資源有限公司在Primrose類似的瀝青洩漏事件。

儘管如此,藻類生質精煉計畫還是會繼續進行,它的目標是大規模測試這項技術的耐久性和可行性。如果這項計畫成功,將成為加拿大和全球工業界回收油砂工業排放廢氣的典範。

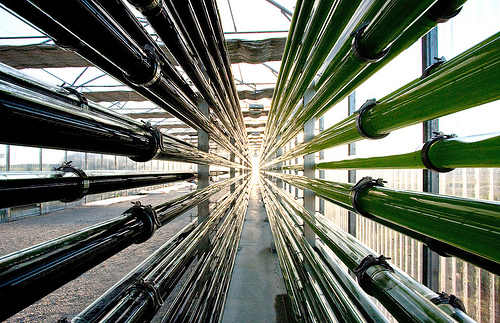

開發商指出,利用封閉式光生物反應器大規模養殖藻類不需要耕地,也不會像生產其他生質燃料一樣和其他農業活動或敏感的生態系統相抵觸。

總部設在多倫多的池塘生質燃料公司執行長馬丁(Steven Martin)表示,「池塘生質燃料公司在加拿大快速成長,我們很高興能和NRC以及加拿大天然資源有限公司合作參與加拿大的油砂計畫。」他提到,「該合作關係與我們現階段為了執行藻類技術而在水泥和鋼鐵部門的運作,是實現加拿大成為全球碳捕捉與回收領域領先地位的重大一步。」

池塘生質燃料公司將來自重工業煙囪排放的煙塵,轉換成藻類生質。藻類是全世界生長最快的有機體之一,它們幾乎能消耗兩倍自身重量的二氧化碳。該公司表示一公噸藻類可以生產100公升以上的柴油,而其餘的生質可用作再生性的煤替代品。馬丁稱呼藻類是「最划算和最能持續的固碳方法。」

這個生物精煉示範廠將用來測試和評估藻類培養技術的擴展性與成本效益,以及是否有商業發展的潛力。研究人員將著重於找出最合適商業發展的藻株、提高產率和降低光生物反應器的成本,同時降低處理藻類生質耗費的能源,並提升藻類生質產品的價值與永續發展。如果Primrose South的生物精煉示範廠成功了,將會擴展到天然資源有限公司在亞伯達省北部麥克莫瑞堡(Fort McMurray)的Horizon油砂計畫,該地生產合成原油。

加拿大政府在5月7日宣布NRC的新結構將轉為著重在「現實的應用與產業的需求」。NRC將和業界聯手銜接技術的差距,幫助加拿大建立更創新的經濟體系。

古德伊爾在5月下旬宣布投資該計畫時表示,NRC將促進產業的利益,並為更強大繁榮的加拿大而努力,藻類碳轉換計畫就是此類結合研究和技術開發的例子。古德伊爾表示,新組建的NRC將提供加拿大產業在全球舞台脫穎而出所需要的策略研究與開發、技術服務和專門的科學基礎設施。

To reduce greenhouse gas emissions from oil production in the Alberta tar sands, the government of Canada is investing in a demonstration-scale algal biorefinery that will convert carbon dioxide into commercial products.

The Algal Carbon Conversion Pilot Project – a partnership among the National Research Council of Canada, Canadian Natural Resources Limited and Pond Biofuels – will result in the construction of a unique, $19 million facility in Alberta.

The three-year project will use algae to recycle industrial CO2 emissions from a tar sands facility into commercial products like biofuels. It will be built at Canadian Natural’s Primrose South tar sands oil production site near Bonnyville, in east-central Alberta.

“This discovery has tremendous potential to benefit our environment and our economy, and further establish Canada as a leader in managing CO2 emissions,” said Science and Technology Minister Gary Goodyear.

The new facility will use carbon dioxide to grow bright green algal biomass. The technology recycles CO2 at the source by incorporating it into algal biomass through photo-synthethis. The algal biomass which will undergo further processing into products such as biofuels, livestock feed and fertilizer.

In addition to mitigating CO2 emissions, algal carbon conversion technology presents an opportunity to remediate wastewater and waste heat.

“Canadian Natural, one of the largest independent crude oil and natural gas producers in Canada, is very pleased to partner with the National Research Council and Pond Biofuels on a project that will lessen our carbon footprint,” said Steve Laut, president of Canadian Natural.

“We are continuously reviewing technologies that offer improved environmental performance in our operations,” said Laut.

But a mix of bitumen and water has been seeping onto the Cold Lake Air Weapons Range in Alberta because of what Canadian Natural calls “mechanical failures” on some of its old wells.

Last week, Canadian Natural said almost a million liters of bitumen had leaked into the environment from four locations at its Primrose East and Primrose South production sites. Primrose South is the site of the demonstration algal biorefinery.

The damage is now contained to a 13.5-hectare area and a “substantial” amount of oil has been recovered. Bitumen is still oozing to the surface, but at “ever-declining” rates, Laut told CTV News.

Canadian Natural uses horizontal wells to inject high-pressure steam into the bitumen reservoir. Alberta regulators have suspended and restricted steaming operations at the Primrose sites and are investigating the cause of the leaks. The Alberta Energy Regulator has reports of similar bitumen leaks from Canadian Natural Primrose sites from as far back as 2009.

Nevertheless, the algal biorefinery project will proceed. Its goal is to test the viability and feasibility of the technology on a large scale. If proven successful, it can then be used as a model for recycling industrial emissions in the tar sands, and in industries across Canada and the world.

The developers point out that large-scale cultivation of algae in enclosed photobioreactors does not require arable land and does not displace agricultural activities or sensitive ecosystems as does the production of other biofuels.

“As a rapidly growing Canadian company, Pond Biofuels is very excited to partner with the National Research Council of Canada and Canadian Natural on this project in the Canadian oil sands,” said Steven Martin, chief executive of Toronto-based Pond Biofuels.

“This partnership, along with our current work with the cement and steel industrial sectors to implement algae technology is an enormous step forward and establishes Canada as the world leader in the field of carbon capture and recycling,” Martin said.

Pond Biofuels converts raw smokestack emissions from heavy industry into algal biomass. One of the fastest growing organisms in the world, algae consume almost twice their weight in carbon dioxide. The company says that one tonne of algae can yield 100 liters or more of diesel, and the residual biomass can be used as a renewable coal substitute.

Martin calls algae “the most cost effective and sustainable means of carbon sequestration.”

The demonstration biorefinery will test and evaluate the scalability and cost effectiveness of algal cultivation technologies for potential commercial deployment. Researchers will focus on identification of most appropriate algae strains for industrial deployment, greater productivity and reduced costs for photobioreactors, reduced energy costs for processing algal biomass and more high-value, sustainable products that algal biomass might yield.

If the biorefinery demonstration plant at Primrose South is successful, it will be extended to Canadian Natural’s Horizon Oil Sands project north of Fort McMurray, Alberta, which produces synthetic crude oil.

On May 7, the Government of Canada announced a shift in focus for the National Research Council with a new structure focused on “real-world applications and on the needs of Canadian business.”

The National Research Council will work with industry to bridge technology gaps, helping build a more innovative Canadian economy.

The Algal Carbon Conversion project is an example of the kind of research and technology development that NRC will pursue in order to benefit industry and contribute to a stronger and more prosperous Canada, said Goodyear, announcing funding for the project in late May.

Goodyear said the newly structured National Research Council of Canada will provide Canadian industry with access to the strategic research and development, technical services and specialized scientific infrastructure it needs to excel on the global stage.

※ 全文及圖片詳見:ENS