瑞典科學家開發出能夠去除病毒粒子的濾紙,效果和目前最尖端的病毒過濾器不相上下。

瑞典科學家開發出能夠去除病毒粒子的濾紙,效果和目前最尖端的病毒過濾器不相上下。

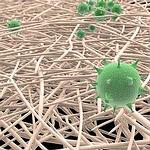

新開發的濾紙以天然萃取的100%高純度「纖維素奈米纖維」(CNF)為原料,並以傳統的造紙方式製作而成。

瑞典烏普薩拉大學奈米科技和應用材料系和瑞典國家獸醫研究所的瑞典農業科技大學病毒學家共同研發出這項新技術,並發表於當期的「先進保健材料」期刊。

排除病毒感染 過濾工具是關鍵

「治療蛋白和疫苗等生技產品遭病毒感染是非常嚴重的問題。病毒很小,難以完全去除,因此亟需便宜又強力的病毒過濾工具。」研究主持人、烏普薩拉大學副教授Albert Mihranyan說。

病毒粒子的大小不到一根人類頭髮的數千分之一,只能在活體細胞內複製,不過一旦病毒成功感染細胞,致病力會變得非常強,能自動引發疾病,或將健康細胞變成惡性腫瘤。

化學過濾過程繁複 便宜、無毒纖維素可望取代

纖維素存在綠色植物中,是地球上最常見的有機聚合物,也是最常用於製造多種纖維的原料。纖維素結構強韌,在強酸和強鹼的環境都很穩定,也能耐受高壓滅菌器的消毒過程,還有便宜、可丟棄、性質穩定又無毒等優點。

一般化學用的濾紙孔洞太大,無法去除微小的病毒,而奈米纖維的直徑小於100奈米,也就是一千萬分之一公尺。而病毒的大小大約30至50奈米,因此奈米纖維過濾紙足以阻擋病毒,發揮過濾功能。

過去的奈米濾紙以靜電相互作用攔截病毒,在強酸和高鹽環境下無法運作,而且過去的奈米濾紙以合成聚合物為原料,以多步驟的相轉化法製作,過程非常繁複,而且需要用有毒溶劑和嚴格的熱處理,才能控制孔隙的大小。

Swedish scientists have developed a paper filter that can remove virus particles with a level of efficiency matching that of the best industrial virus filters. The paper filter consists of 100 percent high purity cellulose nanofibers, directly derived from nature, and is manufactured with traditional papermaking processes.

Researchers at the Division of Nanotechnology and Functional Materials, Uppsala University carried out the research in collaboration with virologists from the Swedish University of Agricultural Sciences at the Swedish National Veterinary Institute. It is published in current issue of the journal “Advanced Healthcare Materials.”

Tiny virus particles, a thousand times thinner than a human hair, can only replicate in living cells, but once the cells become infected the viruses can turn out to be extremely pathogenic.

Viruses can actively cause diseases on their own or can transform healthy cells to malignant tumors.

“Viral contamination of biotechnological products is a serious challenge for production of therapeutic proteins and vaccines,” said Albert Mihranyan, associate professor at Uppsala University, who heads the study.

“Because of their small size, virus removal is a non-trivial task. Therefore, inexpensive and robust virus removal filters are in high demand,” he said.

Cellulose, a component of green plants, is the most abundant organic polymer on Earth. It is one of the most common materials used to produce various types of filters because it is inexpensive, disposable, inert and non-toxic.

Cellulose is also mechanically strong, stable in a wide range of acid and alkaline conditions, and can withstand sterilization in an autoclave.

But normal filter paper, commonly used for chemistry, has pores that are too large to remove tiny viruses.

The newly developed paper filter, which is made according to traditional papermaking processes, consists of 100 percent high purity cellulose nanofibers.

Nanofibers have diameters less than 100 nanometers, a unit of measure equal to one billionth of a meter. By comparison, viruses range from 30-50 nanometers, so the nano-paper filter can serve as a virus barrier.

Previously described virus removal paper filters relied heavily on interception of viruses via electrostatic interactions, which are sensitive to acid-base conditions and salt concentrations.

Virus removal filters made from synthetic polymers are produced through tedious multistep phase-inversion processing that involves hazardous solvents and rigorous heat treatment to control the pores of these materials.

※ 全文及圖片詳見:ENS