新科技具成本減半、每小時達一公噸處理能量等優勢

世界首見且最大型的二氧化碳(CO2)捕集試驗電廠15日於丹麥正式啟用。此捕集設備是利用新科技,從傳統燃煤發電站的排煙道氣體中,截取二氧化碳後儲存於地下儲槽內,因此大可減少此溫室氣體被排放至大氣中,進而遏止全球暖化現象。這項試驗計畫實施地點位於埃斯堡附近的艾爾桑(Elsam)發電廠。

世界首見且最大型的二氧化碳(CO2)捕集試驗電廠15日於丹麥正式啟用。此捕集設備是利用新科技,從傳統燃煤發電站的排煙道氣體中,截取二氧化碳後儲存於地下儲槽內,因此大可減少此溫室氣體被排放至大氣中,進而遏止全球暖化現象。這項試驗計畫實施地點位於埃斯堡附近的艾爾桑(Elsam)發電廠。

這項歐盟啟動的創新計畫名為CASTOR,為「CO2 from Capture to Storage」(捕集二氧化碳到儲存)之縮寫。該計畫集合來自歐洲11個國家的30家公司、研究機構與大學互相合作。

碳捕集與儲存科技,被視為是目前以石化燃料為主的能源系統過渡到未來「零碳排放」能源系統的橋樑。歐盟執委會科學與研究執委波托奇尼克(Janez Potocnik)表示:「在再生能源或無碳能源發展達到普遍使用之前的過渡期間,我們可藉由發展碳捕集和儲存科技來降低碳排放量。」

由法國石油中心(Institut Français du Pétrole,IFP)負責主持的試驗計畫小組,將利用兩年的時間呈現這項科技的效果,以確保能普遍運用於產業界。

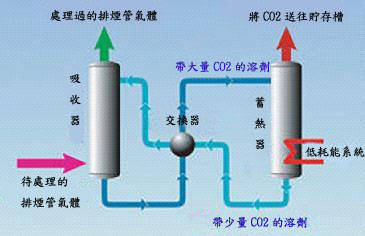

這項CASTOR計畫能捕集到燃煤電廠排煙道所排放氣體中大部分的二氧化碳。處理方式是將排煙道氣體引導到吸收器裡,然後和特定溶劑混合。比起與排煙道中其他的氣體分子,該溶劑與二氧化碳分子的親和性較高,可以捕集排煙道中90%的二氧化碳。

這項CASTOR計畫能捕集到燃煤電廠排煙道所排放氣體中大部分的二氧化碳。處理方式是將排煙道氣體引導到吸收器裡,然後和特定溶劑混合。比起與排煙道中其他的氣體分子,該溶劑與二氧化碳分子的親和性較高,可以捕集排煙道中90%的二氧化碳。

混合大量二氧化碳分子的溶劑接著被導入蓄熱器中。此裝置將溫度加熱至120℃,以便將二氧化碳與溶劑之間的連結切斷。於是二氧化碳就因此獨立出來,並且傳送到儲存槽中。而溶劑則還原到原本的形式,可以在重新注入吸收器中,繼續處理排煙管中的氣體。

排煙管其他的氣體分子則連同剩餘10%的二氧化碳,從吸收器中釋放出去。此外,該設備將採用低耗能的系統來運作,以降低二氧化碳的二次產生。

此裝置的設計目標,為每小時捕集1公噸的二氧化碳。

目前,日本大型工業設施已開始採用的傳統式二氧化碳捕集設備,其成本花費根據預測每公噸二氧化碳介於50到60歐元之間。而艾爾桑電廠的試驗計畫,則預期可將成本減半,每公噸約20到30歐元之間。

這項CASTOR計畫共耗資1,600萬歐元,由歐盟執委會提供一半的資金,其餘則由私人合作公司投資。

CASTOR策略目標是:將歐洲10%的二氧化碳排放(相當於歐洲電廠與工廠排放量的30%)加以捕集並予以地質貯存。

The world's largest pilot plant for the capture of carbon dioxide (CO2) from a conventional power station was opened in Denmark today. It is the first installation in the world to capture the CO2 in the flue gases of a coal-fired power station, so they cannot enter the atmosphere and produce the greenhouse effect responsible for global warming. The pilot project at the Elsam power station near Esbjerg, will demonstrate new technology for capturing carbon dioxide emissions as they are produced by power stations and then storing the CO2 emissions underground.

CASTOR, which stands for CO2 from Capture to Storage, is an European initiative grouping 30 partner industries, research institutes and universities from 11 European countries.

Carbon capture and storage technology is viewed as a bridge from the current fossil fuel-based energy system to one that has near-zero carbon emissions. "By developing technologies for carbon capture and storage, we can reduce emissions in the medium-term as we move to large scale use of renewable, carbon-free energy source," said European Science and Research Commissioner Janez Potocnik.

The pilot CO2 capture unit, coordinated by the Institut Français du Pétrole (IFP), will be operated for two years to demonstrate a new technology on a scale large enough to ensure reliable industrial application.

The pilot unit captures most of the CO2 in the flue gases emitted by the coal-fired power station. The flue gases to be treated are directed to an absorber, where they are mixed with a solvent. Having more affinity with the CO2 molecules than with the other components of the flue gases, the solvent captures nearly 90 percent of the CO2 in the flue gases.

The CO2-rich solvent is then fed to a regenerator. The device is heated to 120 degrees Celsius in order to break the bonds between the CO2 and the solvent. The CO2 is then isolated and transported to its storage place. The solvent, restored to its initial form as CO2-poor solvent, is reinjected into the absorber with more flue gases to be treated.

The other components of the flue gas are discharged from the absorber with the 10 percent of the CO2 that was not absorbed by the solvent. The pilot facility will use a system that can be regenerated with a limited quantity of energy, reducing the generation of secondary CO2.

The pilot installation is intended to capture one metric ton of CO2 per hour.

The cost of conventional processes for CO2 capture in the flue gases of large industrial facilities, already operational in Japan, is estimated at between €50 and €60 per metric ton of CO2. The Elsam industrial pilot is expected to halve the cost per ton of CO2 avoided, to between €20 and €30.

The total pilot project cost of €16 million is about half funded by the European Commission, with the remainder being funded by private partners.

The CASTOR strategic objective is to enable the capture and geological storage of 10 percent of the CO2 emissions Europe, which corresponds to about 30 percent of the CO2 emitted by European power and industrial plants.