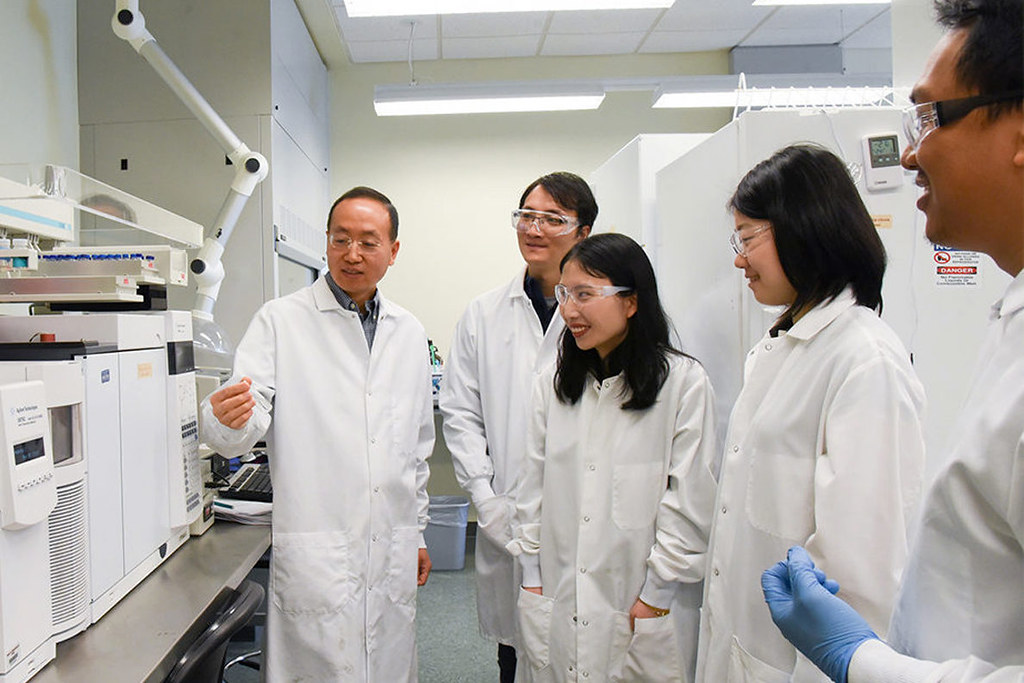

科學家已經找到將塑膠廢棄物轉化為航空燃料的方法。華盛頓州立大學生物系統工程系副教授雷漢武(音譯)帶領的研究小組將塑膠廢棄物在高溫下用活性炭熔化,產生航空燃料。

根據美國環保署最近期統計資料,2015年全美垃圾掩埋場共收集了2600萬噸塑膠。

2018年1月1日起,中國最近不再接收美國和加拿大的塑膠進行回收再利用,禁止24種固體廢棄物進口,包括塑膠瓶中使用的低階聚對苯二甲酸乙二醇酯。

中國過去至少處理了全世界廢紙、金屬和舊塑膠出口總量的一半,2016年為730萬噸。

科學家保守估計,現在全世界每年至少有480萬噸塑膠進入海洋。

在實驗中,雷漢武和研究團隊針對低密度聚乙烯進行測試。他們混合了多種廢塑膠,如水瓶、牛奶瓶和塑膠袋,並將它們磨成米粒大小。接著,將塑膠顆粒置於溫度範圍在430°C至571°C之間的管式反應器中,下方放置活性炭。碳是一種催化劑,能加速化學反應而不被反應消耗。

「塑膠難以分解,必須添加一種催化劑來幫助打破化學鍵。塑膠中含有大量的氫,是燃料中的關鍵成分。」雷漢武說。

一旦碳催化劑完成任務,就可以分離出來並重新用於下一批廢塑膠。催化劑失去活性後也可以再生。

測試不同溫度和幾種不同催化劑的組合,最佳結果是產生85%航空燃料和15%柴油燃料的混合物。

「我們可以從測試的塑膠中回收幾乎100%的能量,燃料品質非常好,副產品氣體品質也很高,具有實用性。」成果發表在《應用能源》(Applied Energy)期刊。

雷漢武說,這個製程很容易擴大規模,可以在大型工廠或農場運作,農民可以自行用塑膠廢棄物製造柴油。

「最終產物必須經分離才能產生航空燃料,如果不分離,就是柴油燃料。」

雷漢武的研究團隊開發出能降低成本並提高生質航空燃料效率的環保催化劑,去年贏得了美國農業部國家糧食和農業研究所50萬美元的資助。

研究人員用酶和玉米秸稈、玉米收穫殘餘物或道格拉斯冷杉樹木屑來產生一種叫做奈米晶纖維素的綠色催化劑。這種催化劑能產生環烷烴石腦油,是航空燃料的主要成分之一。

「為了減少能源和氫氣需求,提高生質航空燃料生產催化劑的性能,我們設計出一種新的催化劑,可以利用環保的天然分子。這些棒狀奈米晶體可以從任何農林業廢棄物取得。」雷漢武說。

Scientists have found a way to turn daily-use plastic waste products into jet fuel. In a method described in a new paper in the journal “Applied Energy,” a research group led by Washington State University Department of Biological System Engineering associate Professor Hanwu Lei melted plastic waste at a high temperature with activated carbon to produce jet fuel.

The U.S. Environmental Protection Agency says that landfills across the country received 26 million tons of plastic in 2015, the most recent year statistics are available. China has recently stopped accepting plastics for recycling from the United States and Canada.

China’s ban, which took effect January 1, 2018, covers imports of 24 kinds of solid waste, including low-grade polyethylene terephthalate used in plastic bottles.

China had been processing at least half of the world’s exports of waste paper, metals and used plastic – 7.3 million tons in 2016.

Now, conservative estimates by scientists say that at least 4.8 million tons of plastic enter the oceans each year worldwide.

In the experiment, Lei and his colleagues tested low-density polyethylene. They mixed a variety of waste plastic products, like water bottles, milk bottles, and plastic bags, and ground them down to the size of rice grains.

The plastic granules were then placed on top of activated carbon in a tube reactor at a high temperature, ranging from 430 degrees Celsius to 571 degrees Celsius. That’s 806 to 1,060 degrees Fahrenheit.

The carbon is a catalyst – a substance that speeds up a chemical reaction without being consumed by the reaction.

“Plastic is hard to break down,” Lei said. “You have to add a catalyst to help break the chemical bonds. There is a lot of hydrogen in plastics, which is a key component in fuel.”

Once the carbon catalyst has done its work, it can be separated out and re-used on the next batch of waste plastic conversion. The catalyst can also be regenerated after losing its activity.

After testing several different catalysts at different temperatures, their best result produced a mixture of 85 percent jet fuel and 15 percent diesel fuel.

“We can recover almost 100 percent of the energy from the plastic we tested,” Lei said. “The fuel is very good quality, and the byproduct gases produced are high quality and useful as well.”

Lei said the method for this process is easily scalable. It could work at a large facility or on farms, where farmers could turn plastic waste into diesel.

“You have to separate the resulting product to get jet fuel,” Lei said. “If you don’t separate it, then it’s all diesel fuel.”

Professor Lei’s efforts to create an environmentally friendly catalyst that could lower the cost and increase the efficiency in producing bio-based jet fuels yielded him and his colleagues a $500,000 grant last year from the National Institute of Food and Agriculture, U.S. Department of Agriculture.

Lei and his team will use enzymes to produce nanocrystalline cellulose, a catalyst. “Green catalysts” will be created from wastes such as corn stover, a remnant of corn harvest, or sawdust from Douglas fir trees. The new nano carbon catalyst is expected to create cycloalkane naphtha, a major component in jet fuels.

“To reduce energy and hydrogen demands, and improve the catalytic performance of bio-jet fuel production, we proposed a new catalyst design that we could leverage from environmentally friendly, nature-based molecules,” Lei said. “These rod-like nanocrystals can be sourced from any agroforestry waste.”

※ 全文及圖片詳見:ENS